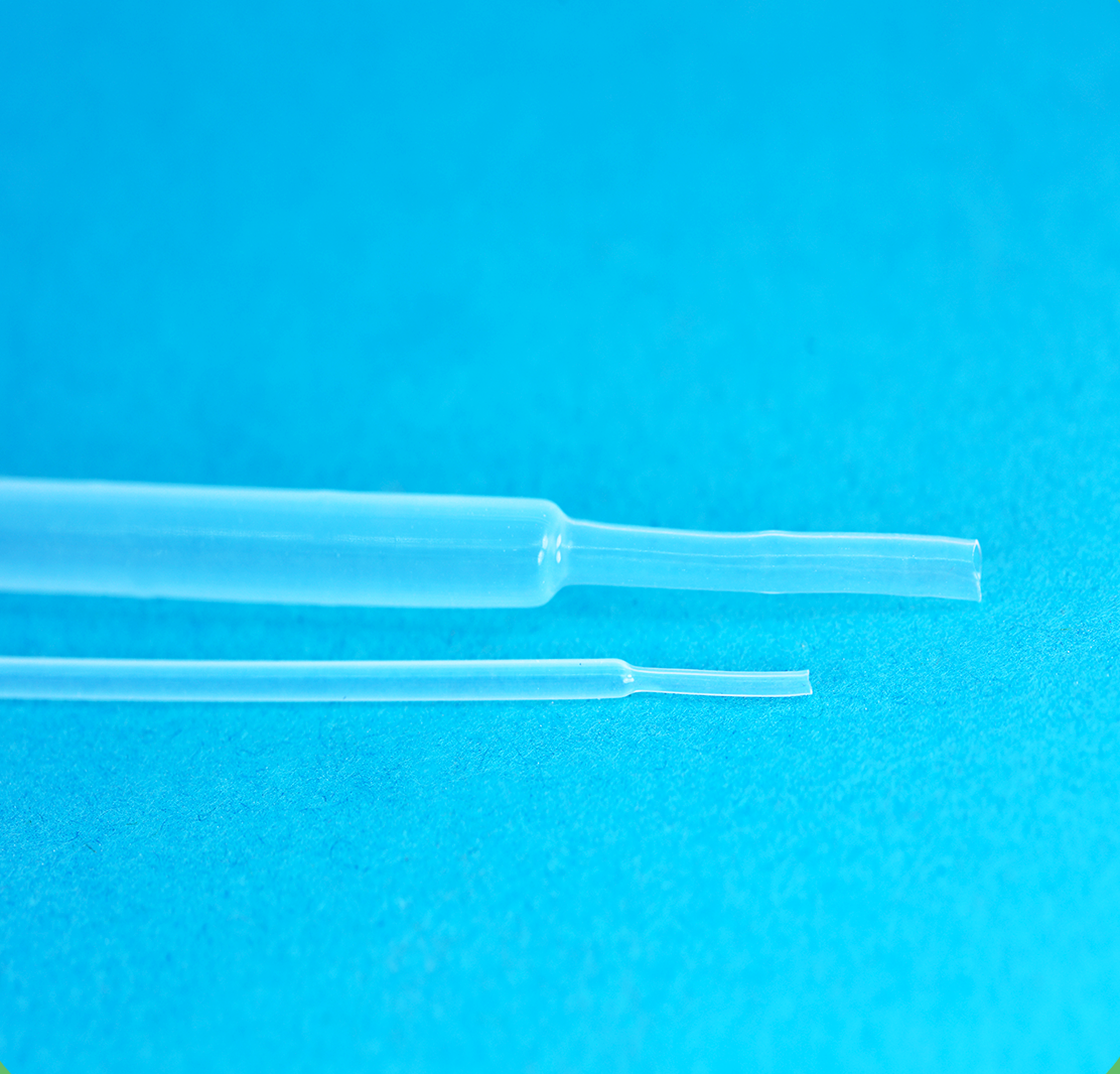

Component Supply offers a complete selection of medical heat shrink tubing designed for medical device engineers, R&D teams, and manufacturing professionals. Our tubing is available in high-performance materials including PTFE, FEP, Pebax, and Polyolefin, and comes in multiple shrink ratios to meet precise design and assembly requirements.

Ideal for catheter construction, minimally invasive medical devices, and prototype development, our heat shrink tubing provides consistent dimensions, reliable insulation, and long-lasting performance in demanding medical applications.

Browse our product lines below to view detailed specifications, material properties, and shrink capabilities, or add products directly to your cart from the chart for fast, efficient ordering. Component Supply ensures quality, availability, and same-day shipping, helping your team keep medical device projects on schedule.

Component Supply provides high-performance heat shrink tubing and other precision components for a variety of industries and applications, supporting medical device engineering, aerospace, electrical, and fiber optic projects.

Explore our full range of materials, sizes, and shrink ratios to find the optimal solutions for your project, whether you are prototyping or producing at scale.

In addition to offering standard lengths, Component Supply provides precision cutting services for all medical heat shrink tubing product lines, ensuring tubing meets your exact specifications for prototyping, assembly, or production. For larger or specialized projects, long lengths of medical heat shrink tubing can be custom ordered to support unique design and manufacturing requirements.

Our fabrication capabilities help streamline production, reduce material waste, and provide consistent, reliable tubing for catheters, minimally invasive devices, and other medical applications.

Component Supply is ISO 13485 certified, ensuring that all our medical heat shrink tubing and other precision components meet the highest standards for quality, safety, and regulatory compliance. Our commitment to excellence supports medical device prototyping, minimally invasive instruments, and production-scale manufacturing.

For detailed quality specifications, material certifications, and compliance information, please refer to the individual product pages.