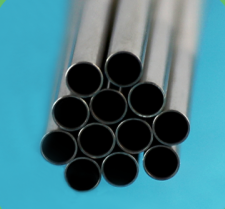

Component Supply’s in-stock stainless steel hypotubes are manufactured from full-hard, welded and drawn 304 or 316 stainless steel, offering strength, consistency, and reliability for medical and industrial applications. Our SS hypotubes are available in gauge sizes from 6 gauge through 33 gauge and in four wall thickness options: regular, thin, extra-thin, and ultra-thin. Standard stock hypotube lengths are 60” and 30”.

For faster prototyping and production support, Component Supply offers same-day shipping on short, burr-free hypotube cuts in the following lengths: 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 7/8”, 1”, 2”, and 3”. We also offer hypodermic tubing lab kits in 304 stainless steel, with 10 tubing configurations designed to support medical device R&D and early-stage testing.

Order medical-grade hypodermic tubing directly by adding items to your cart from the chart below, or click a part number to view detailed specifications, drawings, and related products. Price discounts are available at quantities of 10, 25, 50, and 100, and further volume discounts are available upon request. For custom fabricated hypotubes, please complete our Quote Form for assistance.

Component Supply hypodermic tubing is used extensively in medical device research and development, supporting design, prototyping, and validation activities that require tight dimensional control, material consistency, and reliable performance.

Needle and Cannula Development – Prototyping and development where outside diameter, wall thickness, straightness, and surface finish impact device performance.

Catheter and Minimally Invasive Devices – Structural support, torque transmission, and fluid delivery within catheter systems and minimally invasive tools.

Endoscopic and Visualization Devices – Internal channels and structural components requiring smooth internal diameters and dimensional repeatability.

Drug Delivery and Fluid Management Systems – Controlled fluid transfer and dosing during development and validation.

Prototyping, Testing, and Design Verification (DV) – Commonly used in benchtop testing, proof-of-concept builds, and pre-production validation.

Aerospace – Fluid transmission lines and conduits for harsh operating environments.

Chemical Processing – Corrosion-resistant tubing for chemical fluid transfer.

Laboratory and Research – Chromatography tubing with specialized fittings; sharp and blunt needles for sample collection and dispensing.

Pharmaceutical Manufacturing – Precision pharmaceutical tooling and production equipment.

Tight dimensional control suitable for R&D and production transition

Consistent material quality and lot traceability

Stocked sizes for rapid prototyping and short lead times

CS Custom Fab, the custom fabrication division of Component Supply, provides secondary operations for hypotubes to support medical device R&D, prototyping, and production transition.

Cutting – Precision cutting with standard tolerances of ±0.005″

Bending – Multiple and complex bends to customer-specified radii

Beveling – Per customer drawing and/or specification

Laser Welding – Component and subassembly welding

Notching – Per customer-designated locations

Flattening – Creates oval or flattened profiles

OD Grinding – Tightens outside diameter tolerances

Custom Dispensing Needles – Available in various lengths, wall thicknesses, and two hub options

Consistent with Component Supply’s focus on medical device research and development, CS Custom Fab maintains low order minimums and short lead times for fabricated hypodermic tubing parts. At the same time, we support the volumes, consistency, and documentation required as projects move from R&D into production.

Standard shop minimums typically begin at $250.

Project-specific quotes in 24 hours based on fabrication requirements

Volume pricing and expedite shipping programs available

Material certifications available upon request at no additional charge

Component Supply is committed to providing high-quality hypodermic tubing and fabricated parts that meet the requirements of medical device R&D and production. The following documents and certifications are available upon request:

ISO 13485 Certification – Demonstrates compliance with medical device quality management standards

RoHS Statement – Confirms restriction of hazardous substances in materials

REACH Statement – Ensures compliance with chemical substance regulations

Proposition 65 Statement – Provides information on regulated chemicals for consumer safety

Material Certificates – Free full-composition certificates for stainless steel hypodermic tubing products; check the box at the time of order

304 Stainless Steel Regular Wall Hypodermic Tubing

304 Stainless Steel Thin Wall Hypodermic Tubing

304 Stainless Steel Extra Thin Wall Hypodermic Tubing

304 Stainless Steel Ultra Thin Wall Hypodermic Tubing

304 Stainless Steel Regular Wall Hypodermic Tubing Burr-Free Cut Lengths

304 Stainless Steel Thin Wall Hypodermic Tubing Burr-Free Cut Lengths

304 Stainless Steel Extra Thin Wall Hypodermic Tubing Burr-Free Cut Lengths

304 Stainless SteelRegular Wall Hypodermic Tubing

304 Stainless Steel Thin Wall Hypodermic Tubing

304 Stainless Steel Extra Thin Wall Hypodermic Tubing

304 Stainless Steel Ultra Thin Wall Hypodermic Tubing

304 Stainless Steel Regular Wall Hypodermic Tubing Burr-Free Cut Lengths

304 Stainless Steel Thin Wall Hypodermic Tubing Burr-Free Cut Lengths

304 Stainless Steel Extra Thin Wall Hypodermic Tubing Burr-Free Cut Lengths