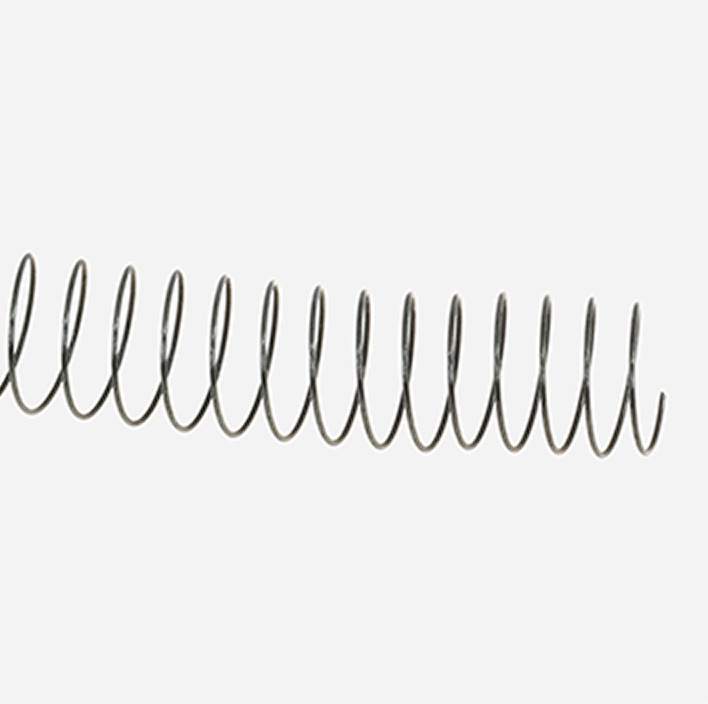

Nitinol mandrels are flexible, kink- and deformation-resistant wires sold in straight lengths and used extensively in the medical device industry for catheter design and development. Made from nickel-titanium, Component Supply nitinol medical mandrels are corrosion-resistant. Nitinol is a paramagnetic metal alloy of nickel and titanium named for its composition and place of discovery: Naval Ordinance Laboratory. Superelastic Nitinol is primarily used for medical device applications requiring superelasticity at room and body temperature. The superelasticity of Nitinol occurs in a narrow temperature range slightly higher than its transformation temperature. Component Supply’s offering of Nitinol wire and mandrels can be strained up to eight times more than ordinary spring steel without permanent deformation and is excellent for shape-setting applications in the medical device industry. Transformation temperatures for superelastic grades are between 10°C and 18°C [50°F and 64.4°F].

Buy standard 36″ and 72″ lengths from the chart below or request a quote for custom Nitinol mandrels.

Superelastic Nitinol medical mandrels and wires have numerous applications in the medical device field including, wire catheter processing mandrels, mechanical switching devices, prosthetics, catheters, superelastic needles, robotic actuators and stents. Component Supply seeks to assist researchers and product designers in determining the best products for their specific applications. While we do provide some information regarding the potential applications of our medical wire and mandrel products, often there are many more possibilities. If you do not see a description for an application suiting your needs, please contact one of our representatives who can give you further information about this product and others that might aid your project.

Custom Fabrication for Medical Nitinol Mandrels includes:

Component Supply offers superelastic Nitinol wires in straight lengths, annealed with a light oxide finish in 36″ and 72″ lengths. We offer production run quantities of this wire, but small quantities are available for testing by researchers and developers as well. We are committed to the innovative methodologies of our researchers and product designers, and we seek to support them by offering small, customized quantities for their specific applications. Our proprietary processes and equipment enable custom fabrication of this material. Talk to one of our reps about shape-setting prototypes, taper grinding, end forming, and precision cutting today!

Fill out our quote form and upload your drawing.

Please see below for applicable standards/certifications and available statements regarding regulatory requirements. Standards are available by lot number and can be requested at the time of order.