When determining the right mesh for your application, there are several key characteristics to understand. Mesh opening, open area percentage, mesh thread, and even thickness will affect the performance of mesh in filtration applications. A minor change to either attribute can completely transform the mesh and its effectiveness in your application.

In this post, we’ll break down the attributes of mesh filtration screen and explain how they are measured and affect the other attributes.

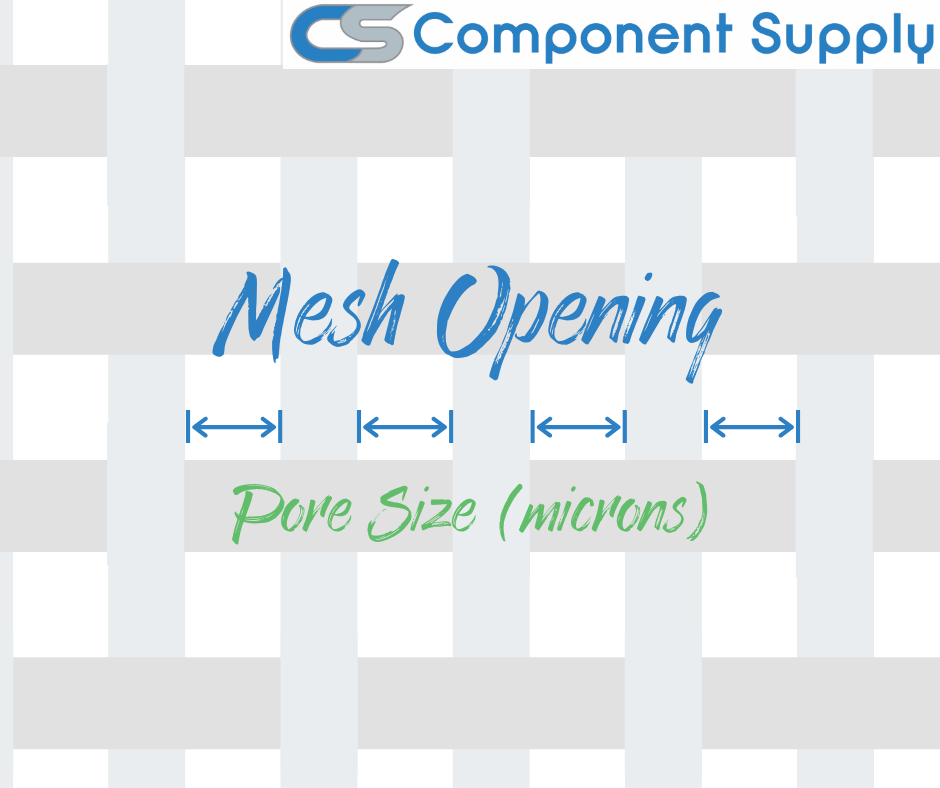

1) Mesh Opening refers to the actual size of the opening or pore size. This is the most critical specification for Component Supply mesh products because it determines the size of the particles it will capture and the size of the particles it allows to pass through. This attribute is specified in microns, a metric measurement equaling one-thousandth of a millimeter.

2) Open area indicates the percentage of a specified area that is open. Open area can help determine what flow restrictions might occur because of the filter.

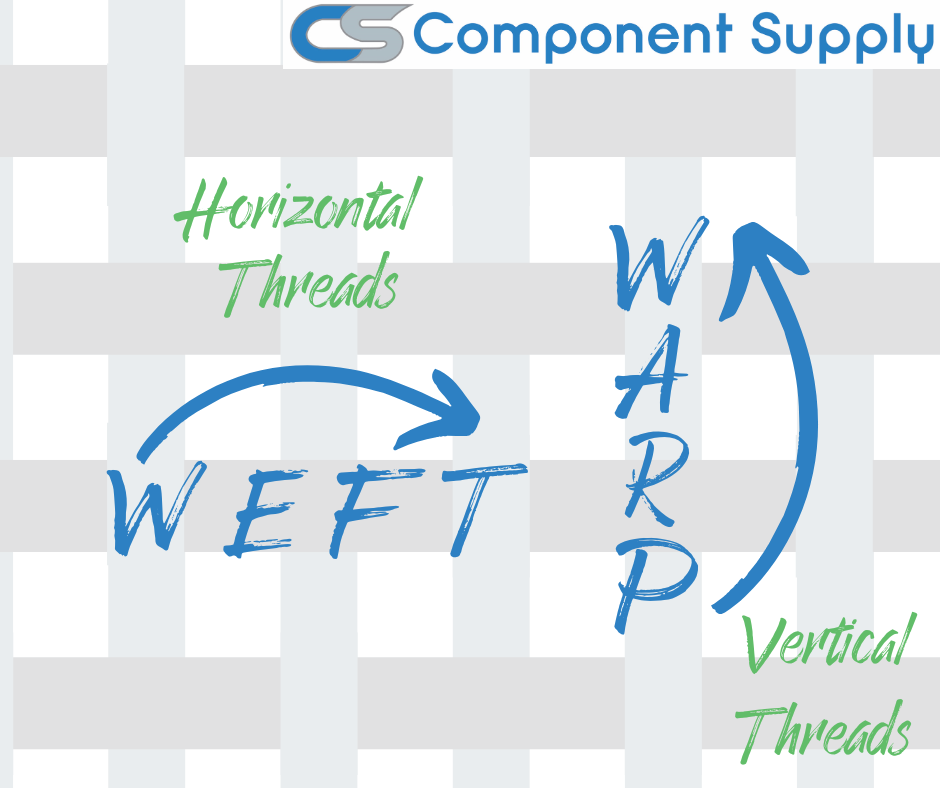

Another way to think about it: Consider a square piece of mesh screen that is 1″x 1″. If you could move all the lateral and horizontal fibers – the warp and weft – up and to one side, you’d be left with some part of the square that is covered by threads and some part that is open. With a mesh that has a 25% open area, the square inch would be segmented into four parts. Three parts (75%) would be covered by the threads, and one part (25%) would be open.

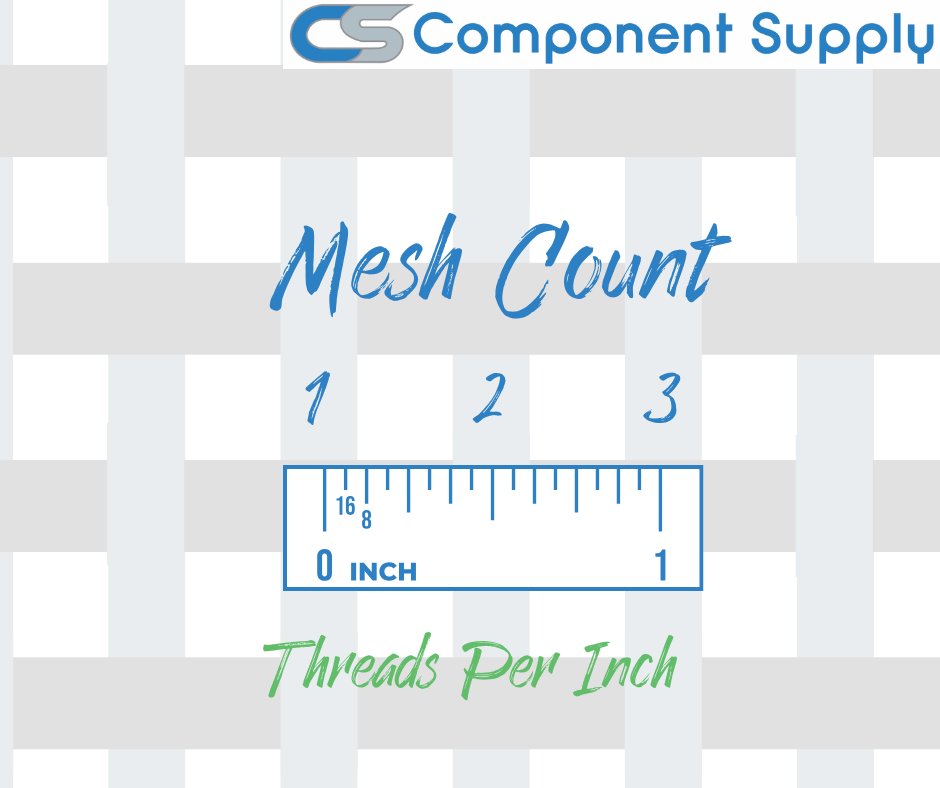

3) Mesh count is the number of threads in a linear inch and is fairly easy to determine. For example, if you were to lay out a piece of mesh and place a ruler on top, then count the horizontal threads from the beginning of the ruler to the one-inch mark, which would give you the mesh count. While this is a simple task for larger mesh opening sizes like our 1000 micron mesh, which has 19 threads per inch, it is daunting and near impossible for some of the smaller mesh sizes. We go as small as 7 microns. For mesh sizes down to about 200 microns, you can count or at least try to count one-quarter of an inch and multiply. For sizes much smaller than that, it becomes difficult without both magnification and some patience.

4) Thread diameter is the diameter of the thread measured in microns.

5) Weight is the weight of the material, typically measured in ounces per square inch.

6) Thickness is the overall thickness of the mesh and is measured in microns.

7) Air permeability measures the rate of air flow passing perpendicularly through the mesh and, for our mesh, is measured in liters (l)/square meter (sq. m.)/second (s).

Bonus: Warp & Weft – The horizontal and vertical threads.

Conclusion

Understanding how mesh properties relate to each other makes selecting the right mesh easier. While there are other sizes available, the specs listed on our site reflect most of what’s out there. If you need something different, don’t hesitate to ask! You can email customer service at parts@componentsupplycompany.com or call 931-761-4000 Monday through Friday from 8:30 am to 5:00 pm CST.

Shop Mesh Products!